Co2-neutral energy generation

Steamergy offers the most innovative total solution for energy generation – specially tailored and optimized for a wide range of biogenic fuelsand the highest customer requirements.

Overview

Our technology

The Steamergy heating and power system is the most economical, CO2-neutral and base load-capable power plant in the electricity, heating and cooling supply sector.

From a technological point of view, our products play a pioneering role worldwide in terms of efficiency and reliability, setting completely new standards in technology.

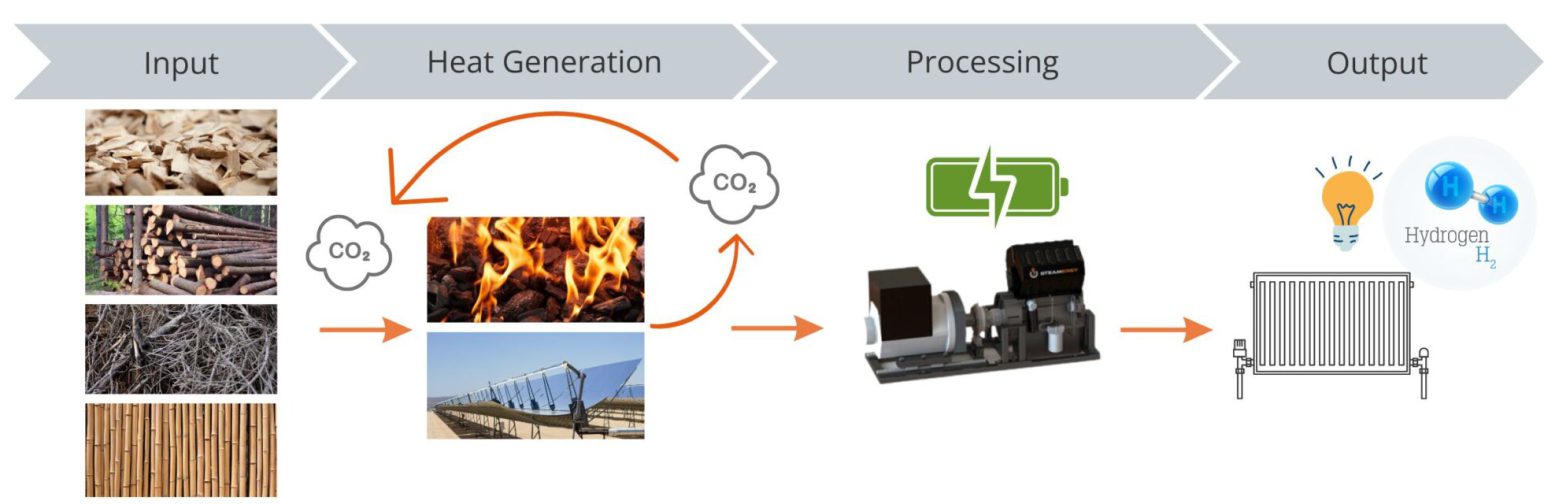

Process chain

How does Steamergy work?

- Biogenic resources such as wood chips, green waste or other locally available fuels are used to supply the Steamergy combined heat and power plant with energy.

- These resources are burned using a parabolic trough in the biomass boiler with automatic fuel feed, whereby the CO2 is released again.

- The combination of Steamergy Liquid Salt Technology (high-pressure steam generator) and the Steamergy high-pressure steam engine forms the basis for unique efficiency and reliability in decentralized biomass power generation.

- This process ensures a stable supply of electricity, heat and hydrogen for our customers.

Technical details

How efficient is Steamergy?

| Technical details | Steamergy |

|---|---|

| Electrical efficiency | 20% – 30% |

| P thermal | 350 – 15.000 kW |

| P electrical | 125 – 5.000 kW |

| Hot water | 50 – 110°C |

| Overall efficiency | > 85% |

| Measures | 20 x 25 x 8.5 meters (depending on layout) |

| Weight | > 50,000 kg (depending on layout) |

| Electrical supply connection | 400V, 50Hz, 63A |

| Primary water content | 150 – 1,000 liters |

| Max. operating temperature | 550°C |

| Max. operating pressure | 130 bar |

| Flow / Return | 4 – 10 inch |

| Operating resources firing | Wood chips, any biogenic residues |

| Oil volume | 300 liters |

Comparison

Comparison of CHP systems with biomass

| Renewable Energy Sources | Steamergy | Wood Gasifier | ORC systems | Steam turbines |

|---|---|---|---|---|

| Power range (kWel.) per module | 125 – 5.000 | 10 – 1.000 | 400 – 10.000 | > 10.000 |

| Overall efficiency | > 85% | > 70% | > 80% | > 80% |

| Electrical efficiency | 20% – 30% | > 20% | 12% – 17% | 20% |

| Process steam | Yes | No | No | Limited |

| Modulability | High | Not given | Limited | Low |

| Fuel costs | Low | High | Low | Low |

| Flexibility of power & heat production | High | Not given | Limited | Limited |

| Maintenance effort | Low | Very high | Average | High |

Benefits

Advantages that are convincing.

Whether large industries, municipalities or medium-sized companies: The Steamergy technology

has already proven itself in many areas of application. Each of them has its own unique requirements profile. But they all have one thing in common: they all benefit from it.

Economical

Secure and available Co2-neutral energy supply with forest residues, wood chips, green waste and other biogenic solid fuels.

Flexible

Use of locally available fuels as well as individually scalable heat and power requirements that can be flexibly

adapted to all needs.

Sustainable

Generating energy from direct sunlight and renewable raw materials is the most efficient and resource-saving way of producing energy.

Cost-efficient

We offer an economical overall solution for sustainable energy projects, both in terms

of resource consumption and maintenance costs.

operationally safe

The Steamergy technology is CE, ISO

and TüV approved.

Low-maintenance

The closed media circuits (water and oil) are constantly regenerated so there is no need for replenishment.

reliable.

eco-friendly. fair.

Steamergy acts as an indispensable element in the global energy transition by ensuring a CO2-neutral, resource-independent, time-independent and weather-independent energy source.